Energy Savings

Reduce energy consumption by 65–81% compared with conventional towers.

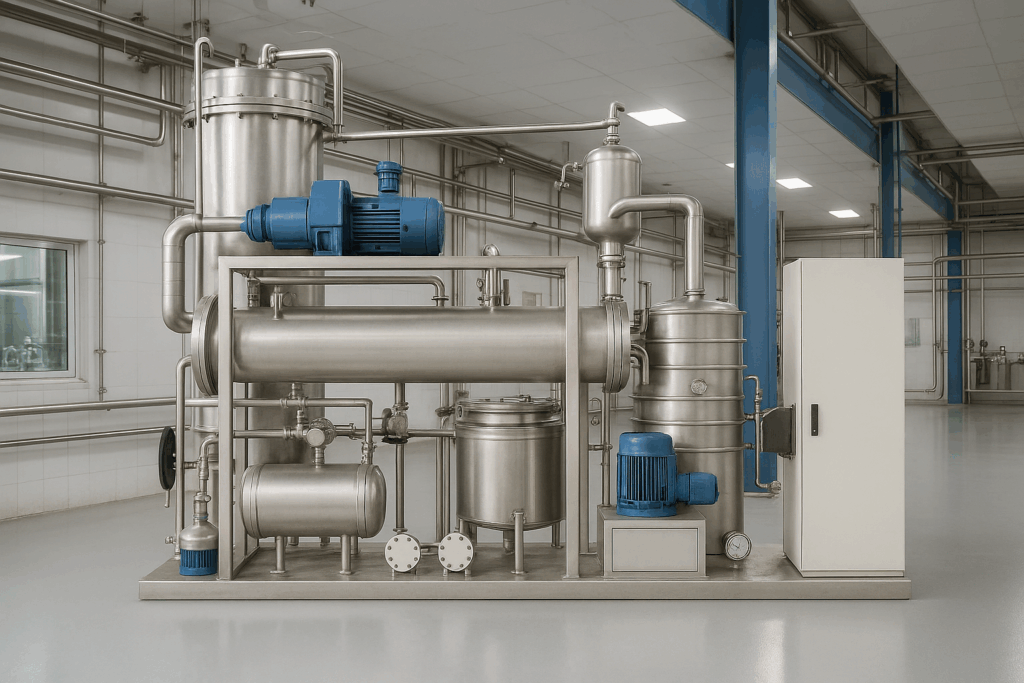

Integrated design combines concentration and distillation in one skid.

The column integrates HiGee separation and heat-pump reboiling into a single, compact structure. This modular, skid-mounted approach minimizes civil works, speeds installation, and simplifies future scale-ups or relocations.

Recycles latent heat to cut energy consumption by up to 40–60%.

The heat pump module captures and reuses vapor heat from the top of the column to supply reboiler duty. This closed-loop cycle slashes steam and cooling requirements, lowers utility bills, and shortens payback time while maintaining stable product purity.

Requires 50–70% less space than traditional distillation towers.

Compared to conventional distillation columns, the modular skid design reduces footprint by over 50%, making it ideal for facilities with space constraints or retrofitting needs. It also lowers construction costs and allows faster deployment with minimal disruption to existing operations.

Get pricing, lead time, and scope based on your spec.

Enter the advantages and introduction of your product here,Enter the advantages and introduction of your product hereEnter the advantages and introduction of your product here,nter the advantages and introduction of

Reduce energy consumption by 65–81% compared with conventional towers.

Skid-mounted system requires far less space.

Efficient heat transfer, faster production rate, and higher product purity

Based in Taixing, Jiangsu, we operate a 200,000 m² facility with 480 sets of advanced machining equipment. Our R&D team collaborates with leading universities such as Zhejiang University, Xi’an Jiaotong University, and Jiangnan University. Certified ISO9000, CE, UL, and ASME, we deliver advanced, reliable, and sustainable separation solutions.

Hear directly from the partners who trust our expertise.

Explore our advanced Supergravity Heat-Pump Distillation solutions, engineered to maximize your recovery efficiency and minimize operational costs.

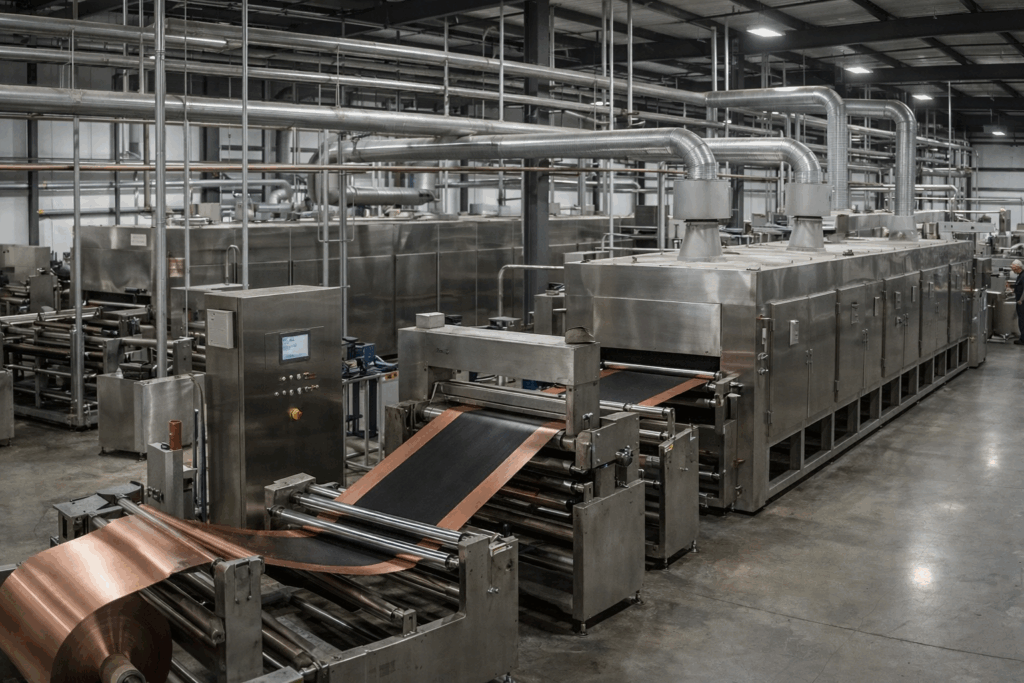

In many industrial processes, chemical solvents are an expensive necessity. They are used to dissolve compounds, control reactions, and support various manufacturing processes across chemical,

Over the years, distillation has remained one of the most critical separation technologies used in various industries. Despite being one of the oldest separation methods,

If you have ever worked on a lithium-ion battery production line, you already know one thing. Solvent recovery always looks simple during the design phase,

Have questions about solvent recovery and distillation? Find quick answers on how our systems fit your process, cut solvent loss and support EHS compliance.

A solvent recovery system helps you recycle and reuse expensive industrial solvents (like IPA, acetone, toluene), reducing chemical purchases and disposal costs—while staying compliant with environmental standards.

Yes, we offer fully customizable systems with lab testing and pilot trials to ensure chemical compatibility and recovery efficiency for your specific use case.

Most clients achieve 80–95% recovery efficiency and full ROI within 6–18 months depending on the volume and solvent type. We also provide cost-saving estimations before purchase.

All systems are CE certified and built in compliance with ATEX and explosion-proof standards where required. We offer detailed documentation and video demonstrations for your audit teams.

Yes—we provide remote and on-site commissioning, 1:1 training, and spare parts support in over 30+ countries. Our English-speaking team is available 24/7 via email, video call, and WhatsApp.